Mfululizo wa SC aloi ya aloi inayoigiza silinda ya kawaida ya hewa ya nyumatiki yenye mlango

Maelezo ya Bidhaa

Kanuni ya kazi ya mitungi ya mfululizo wa SC ni kutumia nguvu ya shinikizo la hewa kusukuma pistoni kusonga kwenye silinda. Wakati shinikizo la hewa linaongezwa kwenye bandari moja ya silinda, pistoni katika silinda huenda chini ya shinikizo, hivyo kusukuma kifaa cha mitambo kilichounganishwa na pistoni. Kwa kudhibiti pembejeo na kutokwa kwa shinikizo la hewa, harakati ya pande mbili au ya unidirectional inaweza kupatikana.

Aina hii ya silinda inaweza kuchagua kaimu mara mbili au modi ya kaimu moja kulingana na mahitaji halisi. Katika hali ya kaimu mara mbili, silinda inaweza kusonga mbele na nyuma chini ya hatua ya shinikizo la hewa; Katika hali ya kaimu moja, silinda inaweza kusonga tu chini ya shinikizo la upande mmoja, na upande mwingine unaweza kuweka upya pistoni kupitia nguvu ya kurudi kwa chemchemi.

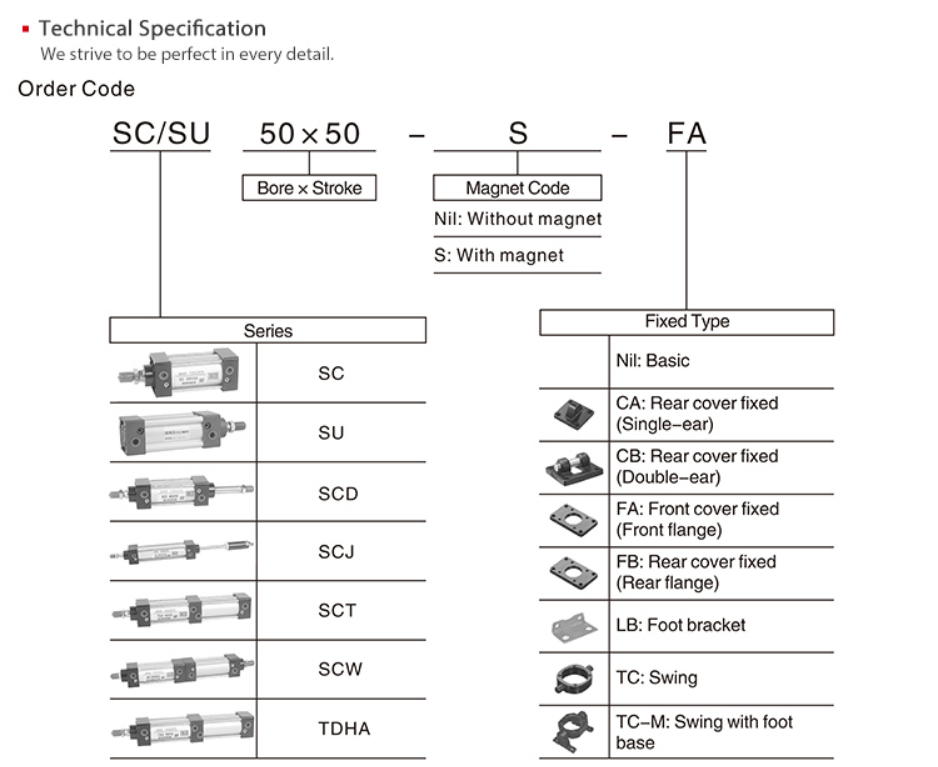

Uainishaji wa Kiufundi

| Ukubwa wa Bore(mm) | 32 | 40 | 50 | 63 | 80 | 100 | 125 | 160 | 200 | 250 |

| Hali ya Kuigiza | Uigizaji Mbili | |||||||||

| Vyombo vya habari vinavyofanya kazi | Hewa iliyosafishwa | |||||||||

| Shinikizo la Kazi | 0.1~0.9Mpa(1~9kgf/cm2) | |||||||||

| Shinikizo la Uthibitisho | 1.35MPa(13.5kgf/cm2) | |||||||||

| Kiwango cha Joto la Kufanya Kazi | -5 ~ 70℃ | |||||||||

| Hali ya Kuakibisha | Inaweza kurekebishwa | |||||||||

| Umbali wa kuakibisha(mm) | 13-18 | 22 | 25-30 | |||||||

| Ukubwa wa Bandari | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | ||||

| Nyenzo ya Mwili | Aloi ya Alumini | |||||||||

| Kubadilisha Sensorer | CS1-F CS1-U SC1-G DMSG | |||||||||

| Msingi Usiobadilika wa Swichi ya Sensor | F-50 | F-63 | F-100 | F-125 | F-160 | F-250 | ||||

Kiharusi cha Silinda

| Ukubwa wa Bore(mm) | Kiharusi cha Kawaida(mm) | Max. Kiharusi(mm) | Kiharusi kinachoruhusiwa(mm) | |||||||||

| 32 | 25 | 50 | 75 | 100 | 125 | 150 | 175 | 200 | 250 | 300 | 1000 | 2000 |

| 40 | 25 | 50 | 75 | 100 | 125 | 150 | 175 | 200 | 250 | 300 | 1200 | 2000 |

| 50 | 25 | 50 | 75 | 100 | 125 | 150 | 175 | 200 | 250 | 300 | 1200 | 2000 |

| 63 | 25 | 50 | 75 | 100 | 125 | 150 | 175 | 200 | 250 | 300 | 1500 | 2000 |

| 80 | 25 | 50 | 75 | 100 | 125 | 150 | 175 | 200 | 250 | 300 | 1500 | 2000 |

| 100 | 25 | 50 | 75 | 100 | 125 | 150 | 175 | 200 | 250 | 300 | 1500 | 2000 |

| 125 | 25 | 50 | 75 | 100 | 125 | 150 | 175 | 200 | 250 | 300 | 1500 | 2000 |

| 160 | 25 | 50 | 75 | 100 | 125 | 150 | 175 | 200 | 250 | 300 | 1500 | 2000 |

| 200 | 25 | 50 | 75 | 100 | 125 | 150 | 175 | 200 | 250 | 300 | 1500 | 2000 |

| 250 | 25 | 50 | 75 | 100 | 125 | 150 | 175 | 200 | 250 | 300 | 1500 | 2000 |

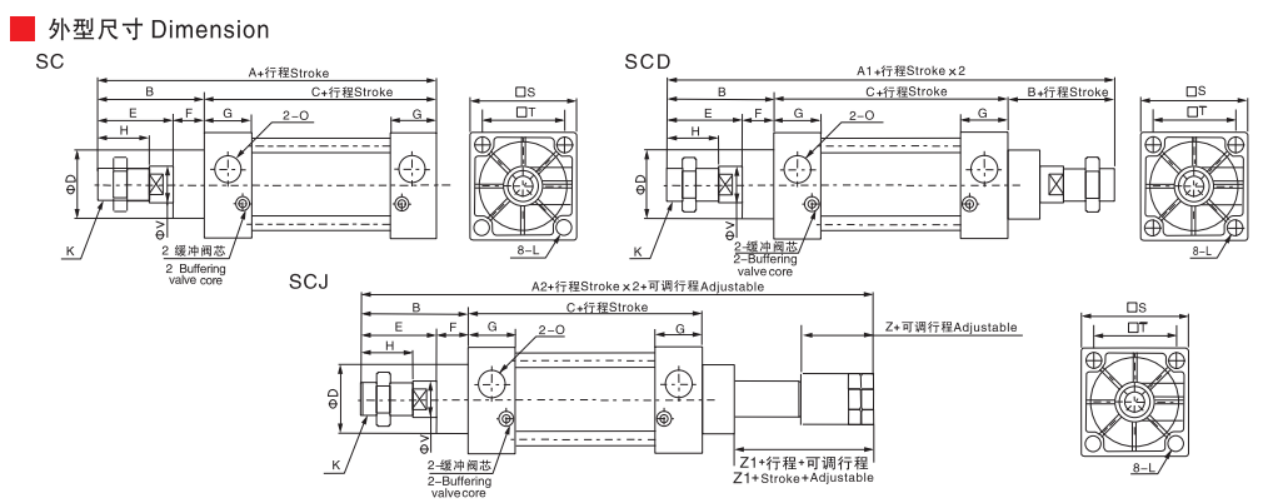

| Ukubwa wa Bore(mm) | A | A1 | A2 | B | C | D | E | F | G | H | K | L | O | S | T | V |

| 32 | 140 | 187 | 185 | 47 | 93 | 28 | 32 | 15 | 27.5 | 22 | M10x1.25 | M6x1 | G1/8 | 45 | 33 | 12 |

| 40 | 142 | 191 | 187 | 49 | 93 | 32 | 34 | 15 | 27.5 | 24 | M12x1.25 | M6x1 | G1/4 | 50 | 37 | 16 |

| 50 | 150 | 207 | 197 | 57 | 93 | 38 | 42 | 15 | 27.5 | 32 | M16x1.5 | M6x1 | G1/4 | 62 | 47 | 20 |

| 63 | 152 | 209 | 199 | 57 | 95 | 38 | 42 | 15 | 27.5 | 32 | M16x1.5 | M8x1.25 | G3/8 | 75 | 56 | 20 |

| 80 | 183 | 258 | 242 | 75 | 108 | 47 | 54 | 21 | 33 | 40 | M20x1.5 | M10x1.5 | G3/8 | 94 | 70 | 25 |

| 100 | 189 | 264 | 248 | 75 | 114 | 47 | 54 | 21 | 33 | 40 | M20x1.5 | M10x1.5 | G1/2 | 112 | 84 | 25 |

| 125 | 245 | 345 | 312 | 100 | 145 | 60 | 68 | 32 | 40 | 54 | M27x2 | M12x1.75 | G1/2 | 140 | 110 | 32 |

| 160 | 239 | 352 | 332 | 113 | 126 | 62 | 88 | 25 | 38 | 72 | M36x2 | M16x2 | G3/4 | 174 | 134 | 40 |

| 200 | 244 | 362 | 342 | 118 | 126 | 62 | 88 | 30 | 38 | 72 | M36x2 | M16x2 | G3/4 | 214 | 163 | 40 |

| 250 | 294 | 435 | 409 | 141 | 153 | 86 | 106 | 35 | 48 | 84 | M42x2 | M20x2.5 | PT1 | 267 | 202 | 50 |

| SQC125 | 245 | 345 | 312 | 100 | 145 | 60 | 68 | 32 | 40 | 54 | M27x2 | M12x1.75 | G1/2 | 140 | 110 | 32 |